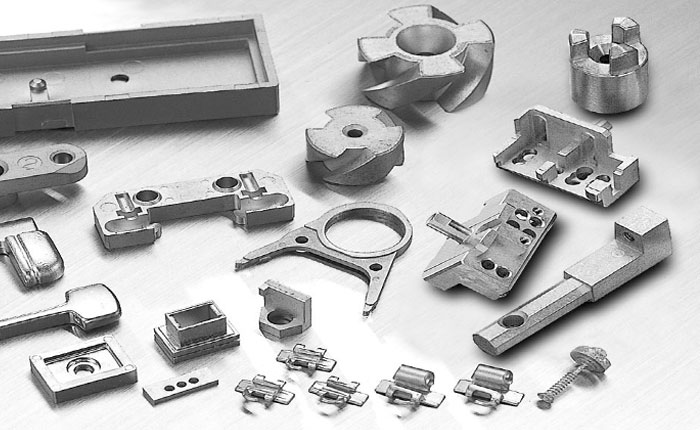

MIM (Metal Injection Molding), It has become one of the most promising and rapidly developing new forming technologies in the field of powder metallurgy, known as one of the most popular metal parts forming technologies in the world.

MIM is a combination of two very different processes (powder metallurgy and plastic injection molding) that allows engineers to break free from traditional constraints and use plastic injection molding to obtain low-cost, shapeless stainless steel, nickel, iron, copper, titanium and other metal parts with greater design freedom than many other manufacturing processes.

MIM process is widely used in consumer electronics, automotive parts, medical devices, industrial equipment, etc.