Quality comes first

Aibet has a highly trained team, and devoted to consistently providing its customers with high-quality products and confident with our testing procedure.

Advanced metallurgy, modern chemical analysis equipment, and statistical process control techniques are used to monitor our process parameters and maintain the highest level of quality. Quality control is built into every stage of manufacturing, from order acknowledgement to delivery, proven by our ISO 9001:2015 certificate.

Also, Aibet assures that all processes are performed in house by certified personnel to meet all specification needs. Meanwhile our employees are cross-trained to support different areas based on workload. Professionally trained and skilled personnel added to over 20 year experiences and a strong commitment to technology, Aibet has earned an excellent reputation, amongst on the international markets.

Inspection steps & processes

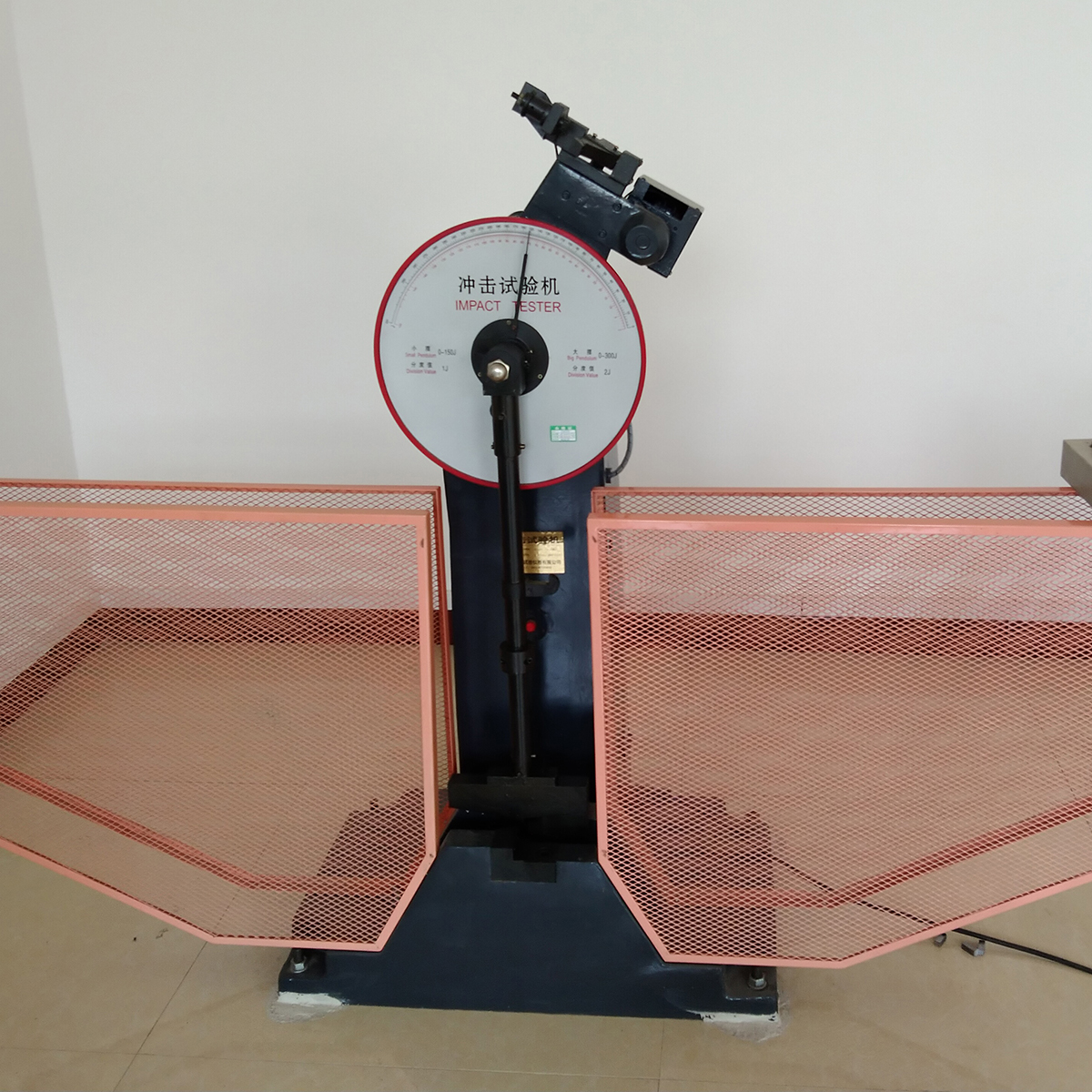

We provide a series of quality control procedures to suit the type of part being manufactured. These processes may include any or all of the following:

- 100% Visual and hand tool Inspection

- Chemical Analysis

- Dimensional Inspection Report

- Hardness Testing

- Tensile Testing

- Ultrasonic Testing

- Magnetic Particle Testing

- NDT Testing

- Coordinate Measuring Machine (CMM)

Quality Assurance

All component parts are fully checked to customers drawing specifications prior to dispatch. Meanwhile we deliver on time as per customer’s requirements.

At Aibet, we always pay attention to every project of the customers.